There is one very fundamental factor and parts of electrical motor that helps when considering treatment of waste to maintain the wellbeing of our communities, and that is the wastewater pump. You may not see them at work, but these pumps are underground doing the heavy lifting, pushing waste to treatment plants. By consuming waste, they prevent flooding and help keep our water clean, all of which makes them a central part of our current sanitation infrastructure. Now, let’s find out why wastewater pumps are so crucial.

Every community contains pipes motor repair that lie underground, transporting waste from our residences and businesses. But how does all of that waste get where it needs to go? That’s where the wastewater pumps come into play. These pumps are the heroes of our sewage systems, transporting dirty water to treatment plants to be purified before its cycle through the environment continues.

Stopping flooding in our communities is one of the key roles that wastewater pumps play. When it rains heavily, that water has to go somewhere. Without the pumps for the wastewater, though, our streets and homes might be flooded. Not only does this create a huge mess, it can also contaminate our water system, which cannot be healthy.

What if the refuse we generate at home and work did nothing but stagnate. It would stink and attract pests and germs. Wastewater pumps ensure that this scenario doesn’t happen by removing waste in a timely manner. This keeps our communities clean and healthy for all.

Outhouses and open sewers were used in the past to dispose of waste. Luckily, with modern systems, we have wastewater pumps industrial motors to do this work for us. These lifts are the unsung warriors of our wastewater systems, plugging away silently to keep our neighbourhoods chugging along.

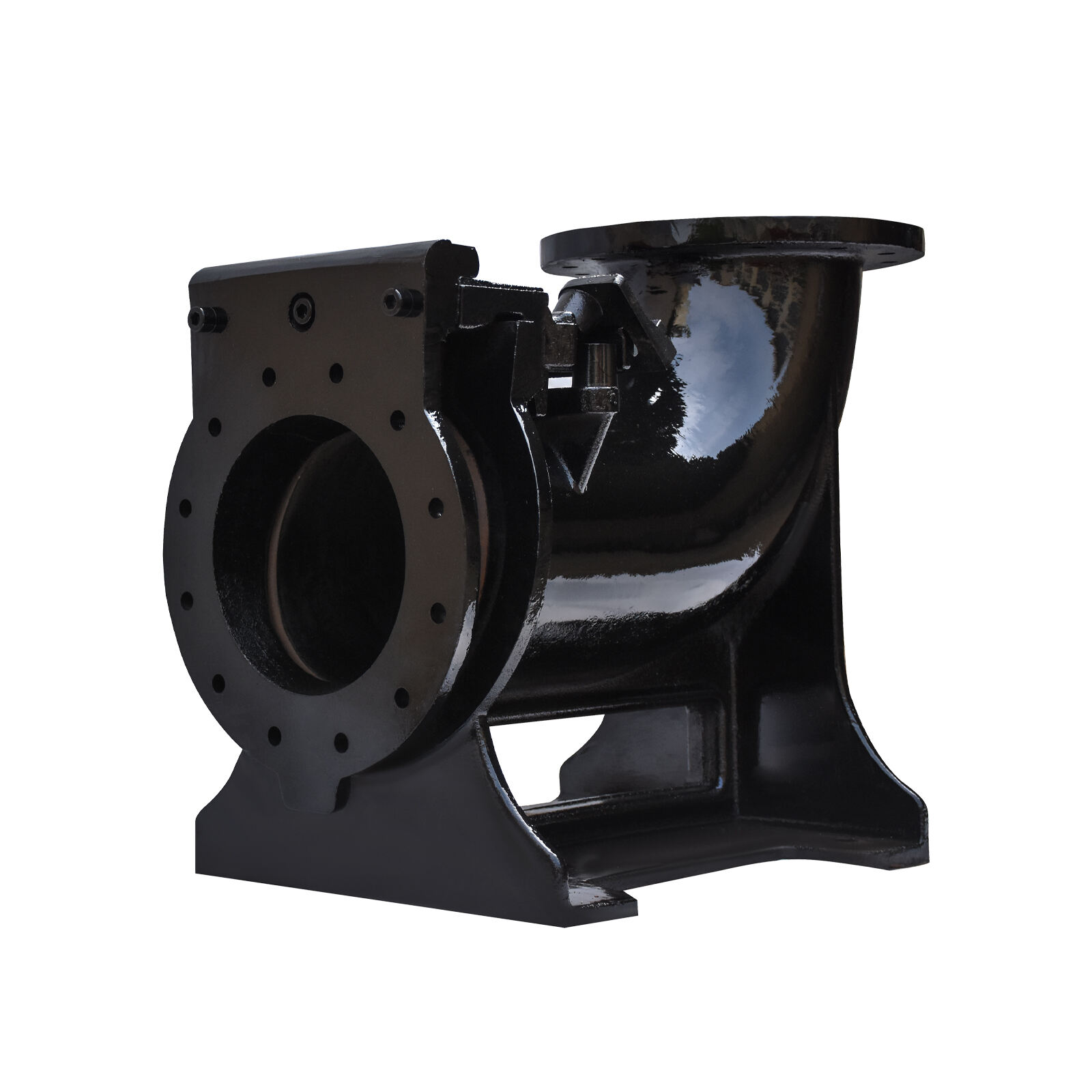

Our energy-efficient motor and pump products are engineered for durability and performance in harsh environments such as mining, agriculture, and industrial sectors, ensuring long-term reliability with minimal maintenance.

As an ISO9001 and coal safety-certified enterprise, we offer complete one-stop services from design and production to installation and after-sales support, ensuring quality, compliance, and customer satisfaction at every stage.

We leverage cutting-edge technologies like permanent magnet drives and frequency conversion control to provide fully customized pump and motor solutions tailored to specific customer needs across diverse applications.

With over 30 years of experience, we operate a 60,000+ square meter modern facility equipped with 300+ sets of advanced automated production and testing equipment, supported by a team of 400+ employees including nearly 100 senior technicians.