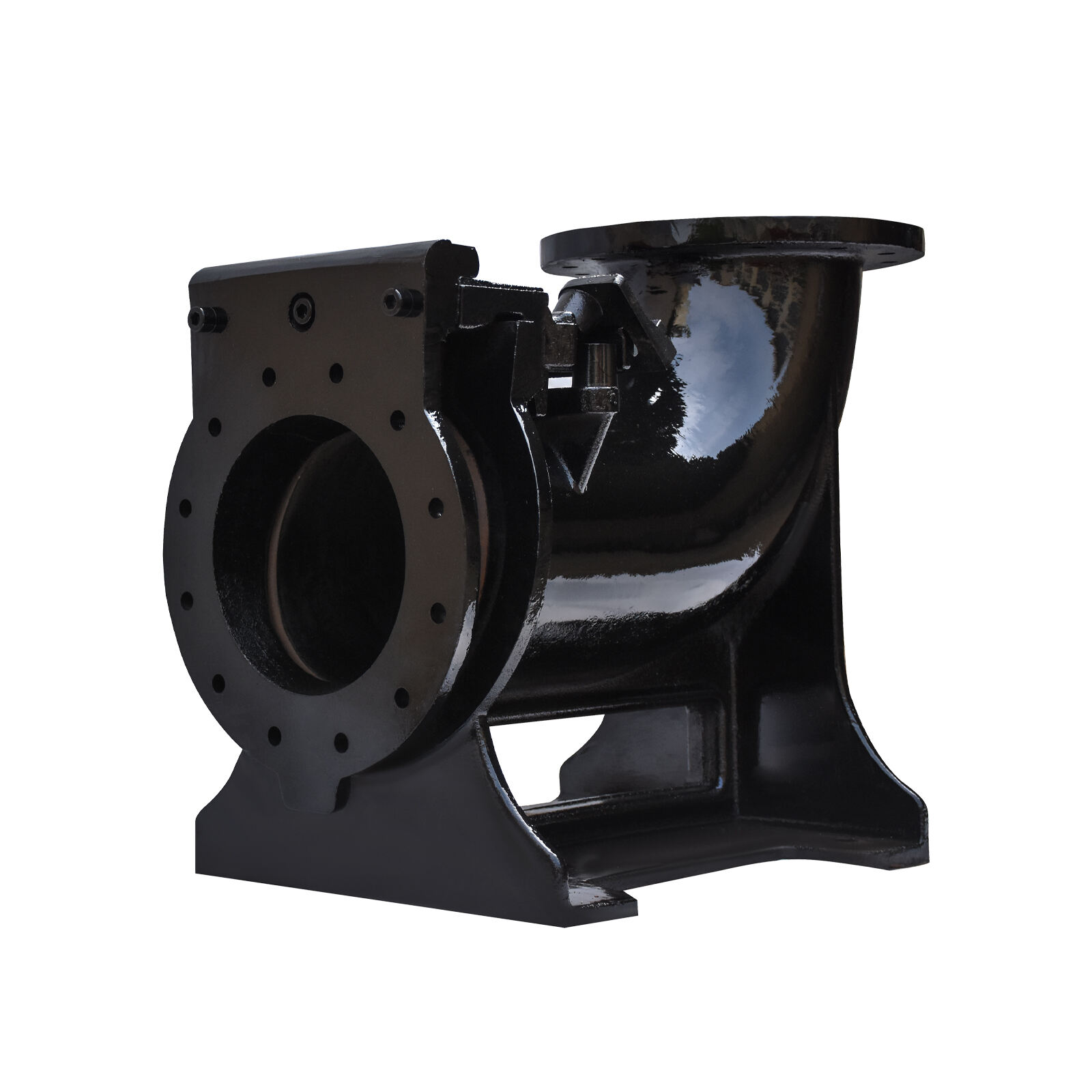

This content is restricted to members Axial Pump. An axial flow pump from Zhaoyangdjby is commonly used to propel liquids in a straight line by utilizing blades. You can imagine it as a huge straw that sucks water and spits it out at the other side. These pump types are frequently used in locations such as farms, factories as well as inside our homes to increase the movement of water and other fluids from one location to another.

An axial pump works by spinning blades at high speed to create a whirlpool that draws water or other liquids into the pump when you activate it. The shape of the blades pushes the liquid in a straight line through the pump as comes in. Fluid dynamics is the study of such movement of liquids. This is critical for the pump to efficiently transport liquids.

If you use axial pumps in factories, they have many applications. One major advantage is that Zhaoyangdjby submersible grinder pump can quickly and efficiently move a great deal of liquid. This can enable employees to accomplish their work more quickly. Additionally, axial pumps are robust and dependable making them ideal option for companies that require continuously efficient machine performance.

There are many factors to consider when selecting an axial pump for your own system. First, you need to consider the size and power of your system so you can choose a pump that will get the job done. You should also consider the type of liquid you are moving it different pumps perform better with certain liquids. Finally, you should also think about how easy the pump is to care for and maintain.

Routine servicing is required to function well and for the longer life of your axial pump. This involves inspecting the pump for any signs of wear or damage, and cleaning and lubricating the blades when necessary. Finally, make sure to consider the motor and Zhaoyangdjby effluent submersible pump parts if such are used. These tips can help your axial pump continue to perform well for years to come.

We leverage cutting-edge technologies like permanent magnet drives and frequency conversion control to provide fully customized pump and motor solutions tailored to specific customer needs across diverse applications.

As an ISO9001 and coal safety-certified enterprise, we offer complete one-stop services from design and production to installation and after-sales support, ensuring quality, compliance, and customer satisfaction at every stage.

With over 30 years of experience, we operate a 60,000+ square meter modern facility equipped with 300+ sets of advanced automated production and testing equipment, supported by a team of 400+ employees including nearly 100 senior technicians.

Our energy-efficient motor and pump products are engineered for durability and performance in harsh environments such as mining, agriculture, and industrial sectors, ensuring long-term reliability with minimal maintenance.